Pcba printed circuit boards

PCBs are an integral part of all modern electronic devices. They are the substrate that supports and connects electronic components such as resistors and capacitors. They are also the base for many complex circuits that are essential to modern devices like computers and mobile phones. They offer a number of benefits over traditional wiring, such as design flexibility and increased reliability. These advantages have made them a popular choice for manufacturers and consumers alike.

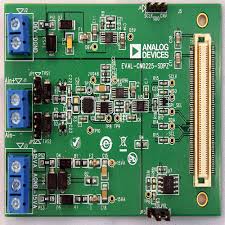

The PCBA (or Printed Circuit Board Assembly) process is the complete process of passing a blank printed circuit board pcba through Plated Through Hole (PTH) and Surface Mount Technology (SMT) processes to assemble all of the electronic components on it. It is typically a very intricate and time-consuming process. The process can involve SMT, hand, wave, or reflow soldering and various forms of quality control inspection.

Choosing the right PCBA manufacturer is essential to ensuring high-quality results and timely delivery. The ideal manufacturer will have experience working with a variety of components and assembly techniques. This knowledge can help ensure that your product meets all of its required specifications and is ready to meet the needs of your target market. In addition, the company should be able to provide you with a detailed Design for Manufacturability report that will offer recommendations to improve your design before it goes into production.

Can Pcba printed circuit boards be used in consumer electronics?

The first step in the PCBA process is known as board stuffing. This involves inserting all of the component pins into their assigned positions on the PCB and then soldering them down. The next step is the placement of surface mount components, which requires precise accuracy. This can be done manually or by using machines equipped with computerized vision systems. These systems are able to identify and pick up tiny parts that are often smaller than a grain of rice.

Once all of the components are in place, the remaining holes must be soldered through and any necessary connections made. This can be a challenging process because the components are small and fragile. It is important to use a high-quality solder that has low melting and curing points. This will help to minimize heat-induced damage to the components and the surrounding board.

Once the populated PCBA has been completed, it is subjected to rigorous testing to make sure that it functions properly. In-process testing is a vital part of the PCBA process, as it allows engineering teams to test the product at every stage of manufacturing to catch any defects or errors before they are shipped to customers. This type of testing can include visual inspections, in-circuit testing, and functional tests. It is important to perform these tests at every stage of the process, as it will prevent costly mistakes and ensure that the finished product is safe and reliable.