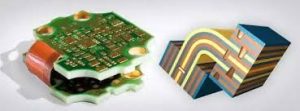

importance of component orientation in Rigid flex pcb

Component orientation plays a critical role in the design and assembly of rigid-flex PCBs, significantly impacting functionality, reliability, and manufacturability. Rigid-flex PCBs, which combine rigid and flexible substrates into a single integrated circuit board, offer unique advantages in terms of space savings, mechanical flexibility, and design flexibility. However, the orientation of components on these boards is crucial to ensure proper functionality, efficient assembly, and long-term reliability in various applications across industries.

One of the key reasons for the importance of component orientation in rigid-flex PCBs is to optimize signal integrity and electrical performance. The orientation of components, such as integrated circuits (ICs), connectors, and passive components, affects signal propagation, electromagnetic interference (EMI), and impedance matching. Proper component placement and routing ensure that signal paths are optimized, minimizing signal distortion, crosstalk, and noise. This is especially critical in high-speed digital and analog circuits where even minor deviations in component orientation can lead to signal degradation and performance issues.

Moreover, component orientation influences mechanical flexibility and reliability in rigid-flex PCB assemblies. Components mounted on flexible regions of the PCB must be positioned and oriented to accommodate bending, folding, and dynamic movement without causing stress, strain, or damage. Improper component orientation can lead to mechanical failures such as solder joint cracking, pad lifting, or component detachment, compromising the structural integrity and functionality of the assembly. By carefully considering component placement and orientation, designers can ensure that rigid flex pcb maintain mechanical flexibility while meeting performance and reliability requirements.

Can you explain the importance of component orientation in Rigid flex pcb?

Component orientation also impacts assembly processes and manufacturability in rigid-flex PCB manufacturing. The orientation of components affects accessibility for soldering, inspection, and testing during assembly. Components with specific orientation requirements, such as polarized capacitors or connectors, must be positioned correctly to ensure proper functionality and alignment with mating components. Additionally, optimizing component orientation can streamline assembly workflows, reduce setup times, and minimize the risk of errors or defects during production. This is particularly important for automated assembly processes where consistency, accuracy, and efficiency are essential for high-volume manufacturing.

Furthermore, component orientation influences thermal management and heat dissipation in rigid-flex PCB assemblies. Components oriented in certain directions may dissipate heat more effectively or contribute to localized thermal hotspots depending on their placement relative to other components, traces, and heat sinks. Proper component orientation is essential to ensure uniform thermal distribution, prevent overheating, and maintain optimal operating temperatures for sensitive electronic components. By strategically positioning components to optimize airflow and heat dissipation, designers can enhance the thermal performance and reliability of rigid-flex PCB assemblies, especially in applications with stringent thermal requirements or operating conditions.

In conclusion, component orientation plays a crucial role in the design, assembly, and performance of rigid-flex PCBs, impacting signal integrity, mechanical flexibility, manufacturability, and thermal management. Proper component orientation ensures optimal electrical performance, mechanical reliability, and assembly efficiency while minimizing the risk of defects or failures during operation. As the demand for compact, lightweight, and flexible electronic assemblies continues to grow, the importance of considering component orientation in rigid-flex PCB design and manufacturing will remain paramount to achieving high-quality, reliable, and cost-effective solutions for a wide range of applications.